Applications of Reduced Graphene Oxide

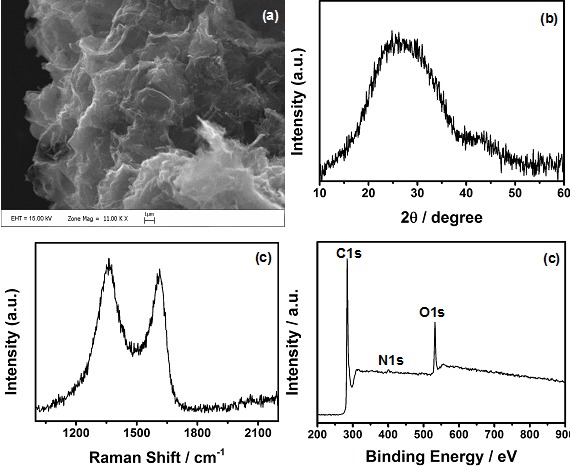

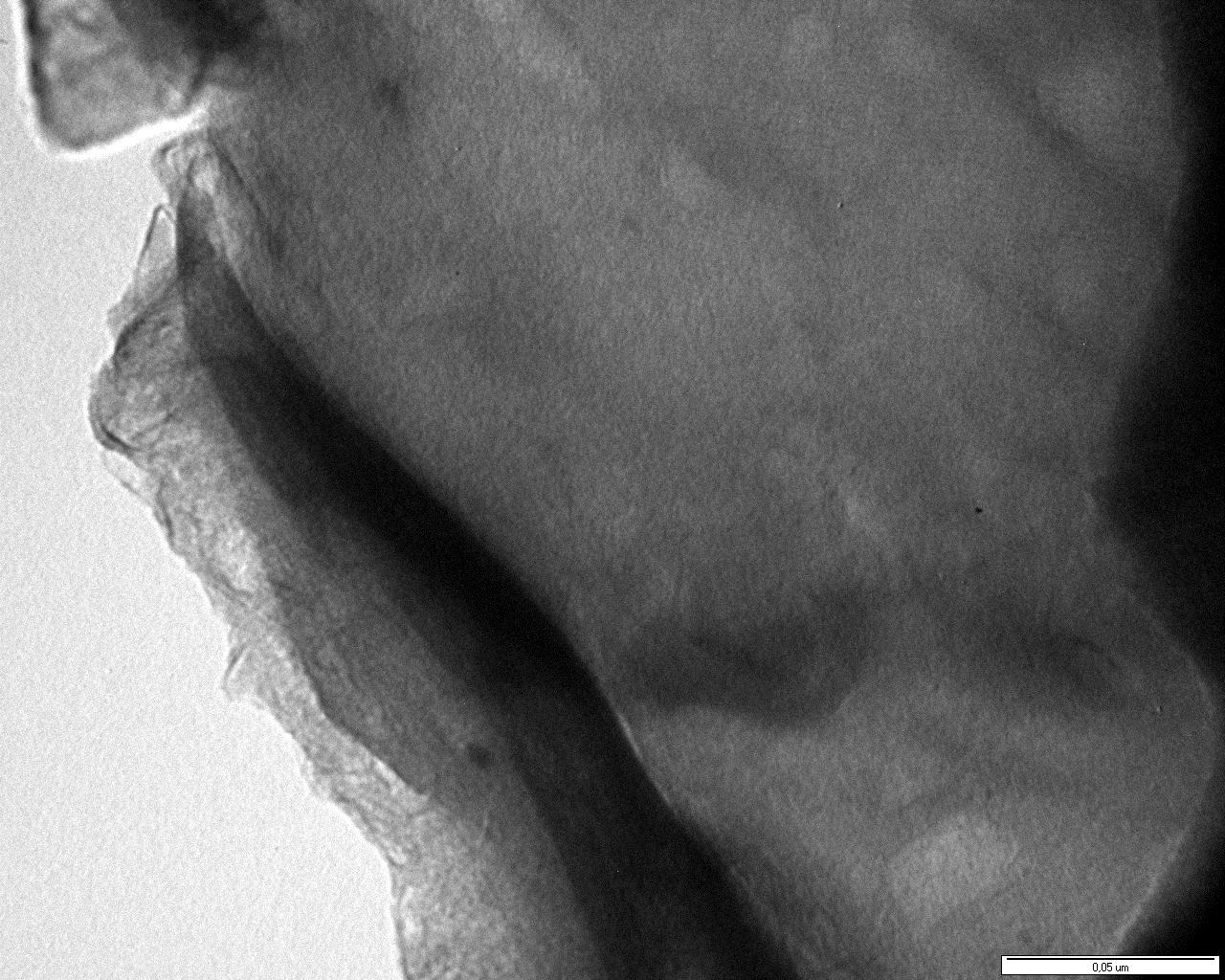

Graphene powder Purity 99% 10g

- Energy Storage

- Biomedical Applications

- Biosensors

- Use as a high performance additive for composites with PPO, POM ,PPS, PC, ABS, PP, PE, PS, Nylon and rubbers.

- Can improve composites tensile strength, stiffness, corrosion resistance, abrasion resistance and anti-static.

- Electricity and lubricant properties.

- For all mechanical properties modifications, typical amounts are about 2-6 wt%

- For conductivity modification, typical amounts are about 2-8 wt%

Additional Information: The addition of Reduced Graphene Oxide (rGO) to different composites show improvements in their physical properties. These improvements include electrical conductivity, thermal conductivity, hardness, strength, viscosity etc. Moreover, graphene can replace materials that are used in today’s applications resulting in enhancement of their applications. For example Reduced Graphene Oxide (rGO)can be integrated into plastics such as epoxy to create a material that can replace steel in the structure of aircraft, improving fuel efficiency, range and reducing weight. It could even be used to coat aircraft surface material to prevent electrical damage resulting from lightning strikes due to its high conductivity.

Graphene in health

The applications of Graphene powder Purity 99% 10g in the health and medicine sectors are also fascinating.

Graphene in electronics

The characteristics of graphene could change the electronics sector completely.

Furthermore, graphene applied to electronic circuits would make devices ‘immune’ to dampness, one of the main causes of deterioration. In addition, it hasexcellent thermal and electrical conductivity, which is 1,000 times better than that of copper.

Graphene in health

The applications of graphene in the health and medicine sectors are also fascinating.

Graphene in electronics

The characteristics of graphene could change the electronics sector completely.

Furthermore, graphene applied to electronic circuits would make devices ‘immune’ to dampness, one of the main causes of deterioration. In addition, it hasexcellent thermal and electrical conductivity, which is 1,000 times better than that of copper.

Reviews

There are no reviews yet.